ALFI Technologies and the Industry 4.0

ALFI Technologies within the Industry 4.0

Many projects, think tanks and associations (Alliance pour l’Industrie du Futur) thrive to reflect on what should be the industry of the future and to develop a factory that is more competitive, more flexible, more communicative, better integrated in its environment and which fosters the development of its employees.

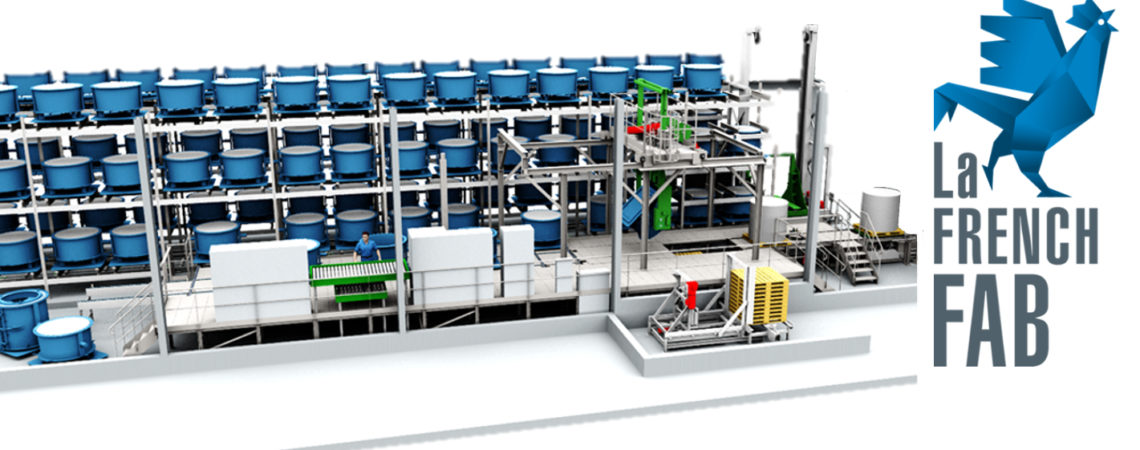

ALFI Technologies offers unique solutions to its customers to help them built the foundations of their factory of the future.

For the ALFI Technologies group, the Industry 4.0 relies on 3 main pillars : human, environnement and technology. Indeed, the group’s mission is to design equipment with lower energy requirements, ergonomic for operators and efficient for customers.

The 3 pillars of Industry 4.0

Innovative and connected factories

- Production information feedback

- Predictive models for parts wear

Humain at the heart of the system

- Reduction of hardship at work

- Reduction of risks for operators

Environmentally friendly factories

- Energy efficiency

- Lightweight material equipment

The fourth industrial revolution is emerging today

It is characterized by an interaction even more important between man and machine, product and machine and between machines themselves. The intensive exploitation of the latest innovations happening in the digital and web sector provides new possibilities allowing to take up the different challenges linked to the 4.0 industry.

The ALFI Technologies group already uses these technologies significantly to design and manufacture its equipment relying for instance on 3D imagery and digital simulation. The group offers many solutions based on the latest digital technologies : robotic units, robots communicating with products, remote control, smart and flexible equipment, visio-maintenance, dematerialization of delivery notes for concrete batching plants, etc… livraison pour les centrales à béton, etc.

These robotic units make it possible to increase productivity but also to improve working conditions in factories. A robotic handling solution developed by the group for the company SOTUBEMA, was awarded “Productivez !” on December, 2014.

A dedicated service offer

Today, ALFI Technologies uses two unique tools to facilitate and accelerate the designing of its clients’ lines and to help them evaluate and validate solutions that have been presented to them before in the decision-making process :

- The Virtual commissioning provides the opportunity to reproduce the automation system of the line before its actual being on-line and to test performances. The group engineers control and validate the program and the man/machine interface from the first stages of the project, thus giving the opportunity to easily move from 3D simulation to real operations.

- Virtual reality, with the Oculus Quest headset: the line is replicated in a virtual environment (digital twin) that stimulates physical presence and enables an interaction with the equipment. It becomes easy to understand how the line works, to check its ergonomics and its organization and to appraise spaces.

Our innovative service activities

3D Modelling and Animation

- Better understanding of the project

- Proactive sharing of information

- Validating spaces

Emulation

- Testing automated programs in a virtual environment

- Anticipating tests before mechanical mounting

- Optimizing testing time on site

Simulation

- Validating paces

- Testing the products’ physical reactions

- Support to get used to the production tool

Training

- Learning by serious gaming

- Training in virtual reality before commissioning