Equipment

ALFI Technologies combines the credibility of 50 years of experience in the installation of production and handling sites for the biggest names, with a unique expertise of digital technologies to design and manufacture with creativity, speed and safety flexible and profitable equipment for its customers.

Flexible and scalable equipment

Vibrating presses

At the heart of the process, single or double row ADLER vibrating presses are associated with semi or fully automated handling lines, automatic or robotized palletizing…

Molds for vibrating presses

Molds from our CS Moules range, are adapted to of all brands and dedicated to the production of standard and special blocks, rectified blocks, slabs, paving, curbs, decorative products…

Cleaning station for presses’ molds

Range of specific equipment to help with cleaning, checking and maintaining the molds of ADLER vibrating presses : easel, gantry with hoist for lifting the pestle, etc.

Chaudronnerie Savoyarde special molds

Special molds for wet cast or semi-dry concrte products : pipes, manhole columns, manhole bottoms, reduction cones… Adapteed molds for delayed or immediate demoulding.

Concrete Activity Supervision

ADLER Smart is a software suite made up of several integrated modules to supervise your entire concrete production process: from the quarry to the plant, until the delivery to the customer.

Demoulding gantry

Our demoulding gantries are suitable for heavy loads (up to 3 tons), for smooth reversal demoulding. The products are unmolded on pallets.

Cleaners

Kiln car cleaner that performs the functions of dust removal and evacuation of shards with non-contact suction, reducing stacking faults and increasing the life of the wagons.

Paquetizers

Unstackers and packers adapted to high speeds production. Versatile, scalable and extremely reliable equipment ensuring high productivity on your production site.

Kiln cars

Our kiln cars handling solutions offer great reliability and proven robustness. Additional wagon equipment: wagon wheels, automatic lubricators, etc.

Cutters

ALFI Technologies integrates a wide range of cutters into its solutions : water jet cutters, wire cutters or saws to meet the specific needs of each customer.

Loaders and unloaders

Loader and unloader allowing the high-speed supply of the lines while preserving the qualities of the products. High speed loading and unloading solutions.

Dryers

Rapid mobile rack dryer with new technologies for faster, more compact and more energy efficient dryers. The ANJOU dryer brings more precision, flexibility and reliability to customers.

Curing ovens

ACC curing ovens are designed to minimize operational costs and maintenance costs, thanks to predictive maintenance guaranteeing increased protection against fire.

Forming

Forming with pallets equipment for the manufacture of mineral wool mattresses. Suitable for green binders, maximum sealing and cleaning options adapted to customer needs.

Packing

These modular packaging solutions are easy to integrate into your production lines and can have a very high resistance to compression if necessary.

Stacking

Wide range of fully automated stackers: fork technology for flexibility (STF range), directly onto the pallet (STP range) or curtain solution for higher speeds (STC range).

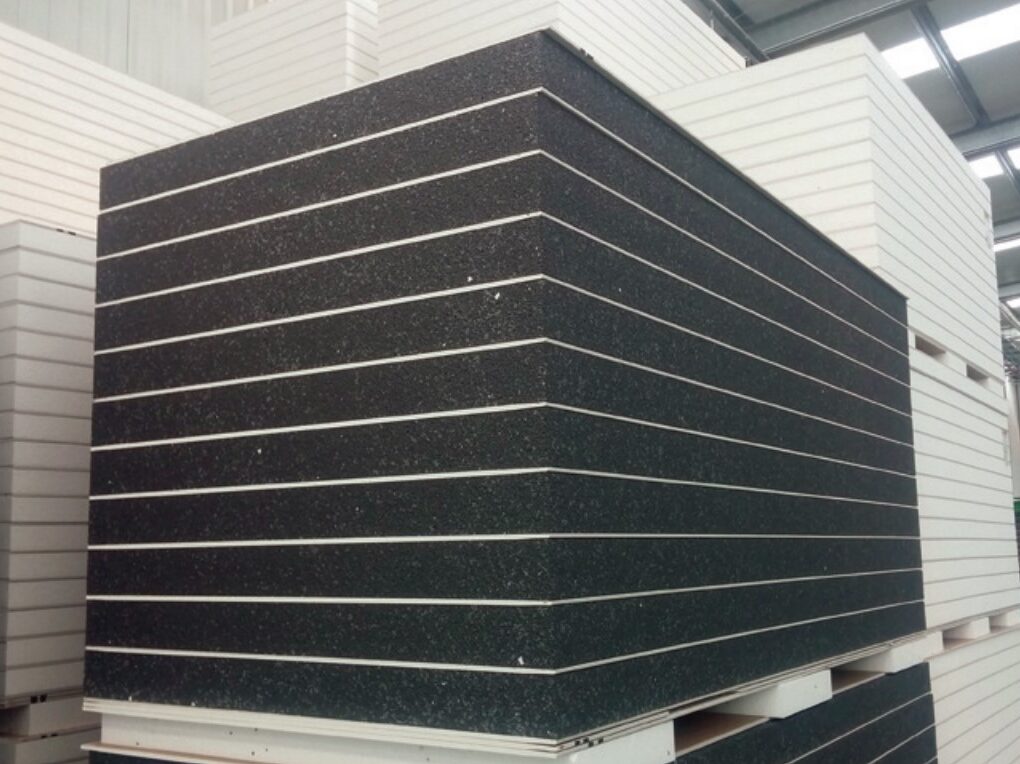

Boards and laminated

Equipment for the manufacture of insulating plates and panels, with machining, cutting or painting processes that can be added to standard production lines.

Not pallet palletizing

Our palletizing solutions are also suitable for no pallet palletizing or packaging. Packaging on wooden pallets is replaced by wedges insertion.

Quality control

The ALFI Technologies group has developed conveying solutions and handling systems that allow quality control operations on the different products.

Destacker

Destackers manufactured by ALFI Technologies are capable of destacking a wide variety of products. Equipment adaptable to production lines and customers’ products.

Conveying

Tailor-made solutions for the conveying of products on your production lines. Ergonomic, optimized and efficient systems to meet customer requirements.

Robotized units

ALFI Technologies integrates in its offer numerous robitized solutions with simplified user interfaces, for the handling of heavy and bulky products or for palletization.

Parcel tipper

U-CARE is a wide range of high-performance parcel unloaders that can unload all types of containers (gaylords, pallets, rolling cages…) onto your conveying lines.

Telescopic conveyors

Large and high-capacity telescopic belt conveyors, enabling an easy loading / unloading of your products into / from transport trucks.

Singulation

Fully automated and efficient parcel singulator. Enables to optimize the flow of parcels on conveyor lines in postal and e-commerce sorting centers.

Palletizing

Intelligent and flexible turnkey palletizing solutions. Versatile and high-performance robotic equipment for palletizing a wide variety of products.

Automated storage

ALFI Technologies automated storage solutions allow greater storage capacity, rapid handling of bulky products and ensure high precision.

Weighing

Gantry weighing machine. This equipment accurately checks the weight, width and diameter of the products. Possibility of adapting the characteristics according to the needs.

Unpacking

Unpacking station for rolled up paper reels. Possibility to adapt the characteristics of the station according to customer needs (angles of rotation speed of rotation).

Handling by gantry

Pick-up, transfer and deposit of a batch of products from one point to another.

Taken from below and held during transfer to avoid the risk of tipping.