Forming section technologies

Thanks to ACC technologies, ALFI Technologies proposes modular and efficient forming solutions. Our forming equipment makes it possible to produce insulating panels with exceptional quality.

Mineral wool panels production unit

The modular conception of the forming section enables to collect output of 2 to 10 fiberization heads. It enables production of mineral wool mattress with a width from 1000 mm to 2500 mm.

- Modular design

- Highly efficient conveyor cleaning

- Reduced fiber looses

- Efficient sealing

Forming with pallets

Ready for green binder

Enchanced protection of mechanical components against corrosion linked to new binders.

Cleaning options

A range of cleaning options adapted to your specification.

Efficient sealing

The design is designed to minimize air and material leaks.

Equipment’s capacity

- Width : 1000 – 2600 mm

- Speed : 80 m/min

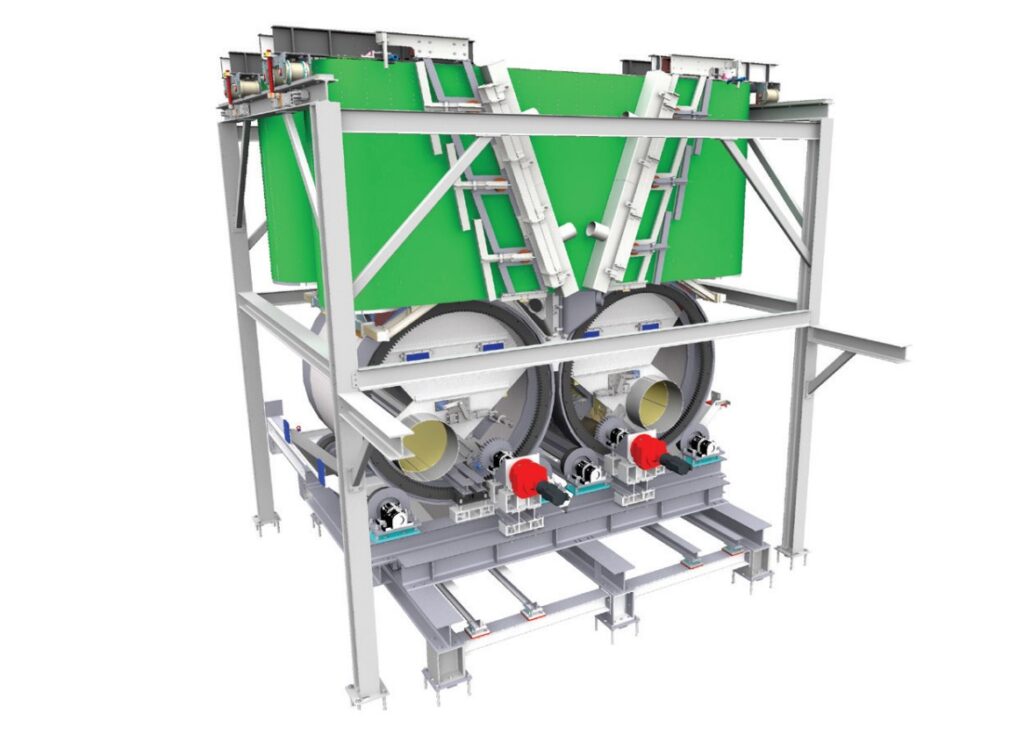

Low pressure forming with drums

This technology enables to produce very high density of glass wool (8000 g/m²) This equipment also offers :

- Cost reduction for Energy consumption up to 80% compared to Flightconveyor technology

- Cost and time reduction for maintenance

- Product optimization with 80% less scraps

- Better quality product thanks to a better distribution of the air flow

Equipment for white blowing wool

ALFI Technologies also offers a solution for the production of blowing wool. It proposes :

- Stainless steel hood

- Improved flight conveyor technology

- Cleaning options : motorized brush for flights, impact ject in suction boxes, high pressure ramp for cleaning

- Central lubrification unit