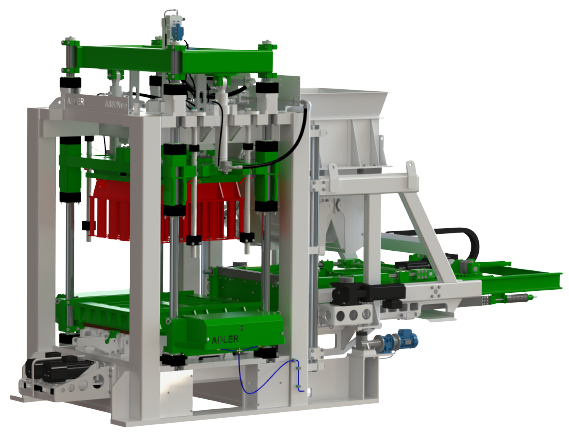

ADLER A880 press

Large format block making machine

An innovative design to produce conventional or light quality blocks with mastered cost efficiency. The A880 press incorporates all the latest innovations developed by ALFI Technologies: control of tamper effort , computarized adjustment of stops, compression time self-correction …

Molding capacity of the A880 block making machine

| Model | Number of products | Production /8h | Molding surface | Max. products height blocks pavers | Max. products height kerbs |

|---|---|---|---|---|---|

| A880 M1 | 10 blocks (20x20x50 cm) | 20 000/25 000 | 1 170 x 1 340 mm | 40/330 mm | 300 mm |

| A880 M2 | 12 blocks (20x20x50 cm) 18 blocks (20x20x40 cm) | 23 000/28 000 | 1 340 x 1 340 mm | 40/330 mm | 300 mm |

| A880 M3 | 18 blocks (20x20x40 cm) | 30 000/35 000 | 1 340 x 1 340 mm | 40/500 mm | 500 mm |

Pallets size

| Model | Front width (mini/maxi) | Length (mini/maxi) | Wood boards thickness | Steel boards thickness |

|---|---|---|---|---|

| A880 M1 | 1 250 mm | 1 400 mm | 45/65 mm | 12/15 mm |

| A880 M2 | 1 450 mm | 1 400 mm | 45/65 mm | 12/15 mm |

| A880 M3 | 1 450 mm | 1 400 mm | 45/65 mm | 12/15 mm |

Customer testimonial

“Le groupe Chavigny s’est doté d’une nouvelle presse Adler grand format A880 en 2017 sur son site de Mettray. Après trois années d’exploitation, je vois le gain apporté par cette nouvelle conception de presse.

La régularité de production est remarquable. La conception du châssis et le massif en béton font disparaître les vibrations résiduelles et il n’est pas nécessaire de changer sans cesse les réglages. Les blocs sortent avec une hauteur régulière et maitrisée à 1 mm.

Nous constatons aussi une très nette augmentation de la durée de vie des moules, d’environ 50%, sur le site de Mettray par rapport à nos autres sites, ce qui nous permet de réaliser des économies substantielles.

La presse A880 est innovante et performante, ses qualités sont confirmées par 3 ans de production à un rythme industriel. Elle permet au groupe Chavigny un gain en terme de qualité et de couts de production.”

Stéphane GRAVIER, Directeur Industriel CHAVIGNY INDUSTRIE