Automated palletizing on rack

Solutions with multifunctional robotized units

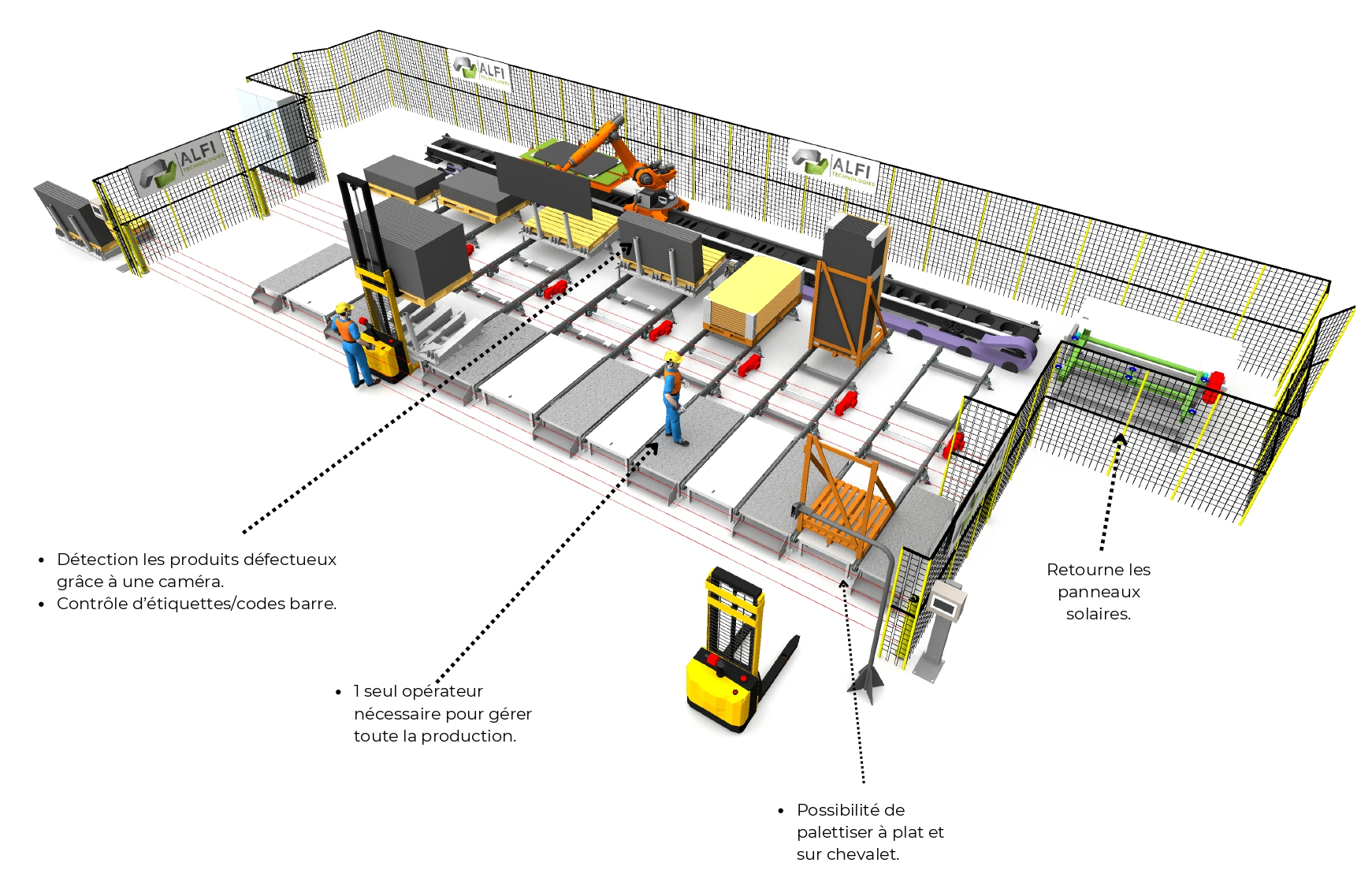

The automated palletizing solution developed by ALFI Technologies meets the productivity, flexibility and quality challenges faced by manufacturers.

Designed to facilitate the handling of products of different dimensions, this solution reduces the tediousness of operations and improves operator safety. By integrating systematic quality control, optimized storage and complete traceability, it guarantees efficient and profitable order preparation.

Adapted to a variety of sectors, including solar panels and carpentry, take advantage of a scalable, reliable solution focused on people, performance and sustainability.

The advantages of our rack-mounted palletizing solutions

Operator

- Fewer strenuous operations

- Can concentrate on quality control tasks

- Developing skills in equipment control and diagnostics

- Easier participation in continuous improvement initiatives

Operator

- Increased profitability, rapid payback.

- Better management of daily planning

- Accompanies your pace

- Traceability of palletized references

Product

- Suitable for all panel sizes up to 2m200

- Bar code check on each panel.

- Horizontal and vertical storage possible

- Control and disposal of non-conforming products

- Securing the pallet before removal

Case study: an automated solar panel preparation and storage solution

ALFI Technologies has developed an automated palletizing solution specially adapted to these sensitive products, with dimensions of up to 2.2 meters.

A robotized order-picking line takes charge of the panels, checks their barcodes and conformity, then positions them on dedicated racks, guaranteeing their integrity. Non-conforming products are automatically discarded, while pallets are secured before removal, ensuring uninterrupted flow.

A scalable solution from automated panel preparation…

Panels are bar-coded, inspected and optimally positioned to reduce the risk of damage.

Non-conforming parts are automatically discarded, guaranteeing uninterrupted flow and consistent quality.

Automation frees the operator from repetitive and tedious tasks. He can devote himself to quality control and supervision, contributing to an overall improvement in working conditions. As for the operator, he benefits from rapid amortization, better planning, and easier ramp-up.

From order picking to automated warehousing

By integrating an automated stacker crane storage system, this solution optimizes available space, adapts to variations in demand and offers complete traceability.

Connected to the Warehouse Management System (WMS), our stacker cranes ensure intelligent inventory management, simplify logistics and enhance safety.

Together,these storage systems make automated palletizing on racks a real opportunity for sustainableperformance for manufacturers.

The advantages of integrating a stacker crane at the end of a palletizing line

Optimizing storage space

Stacker cranes optimize

ideal storage for solar panels in large warehouses

Adaptability to variations in demand

Stacker cranes manage peaks in activity while accelerating orders.

Traceability and intelligent management

Connected to the WMS, stacker cranes ensure traceability and simplify logistics.

Enhanced safety and risk reduction

Automation reduces handling-related accidents and ensures a safer working environment.