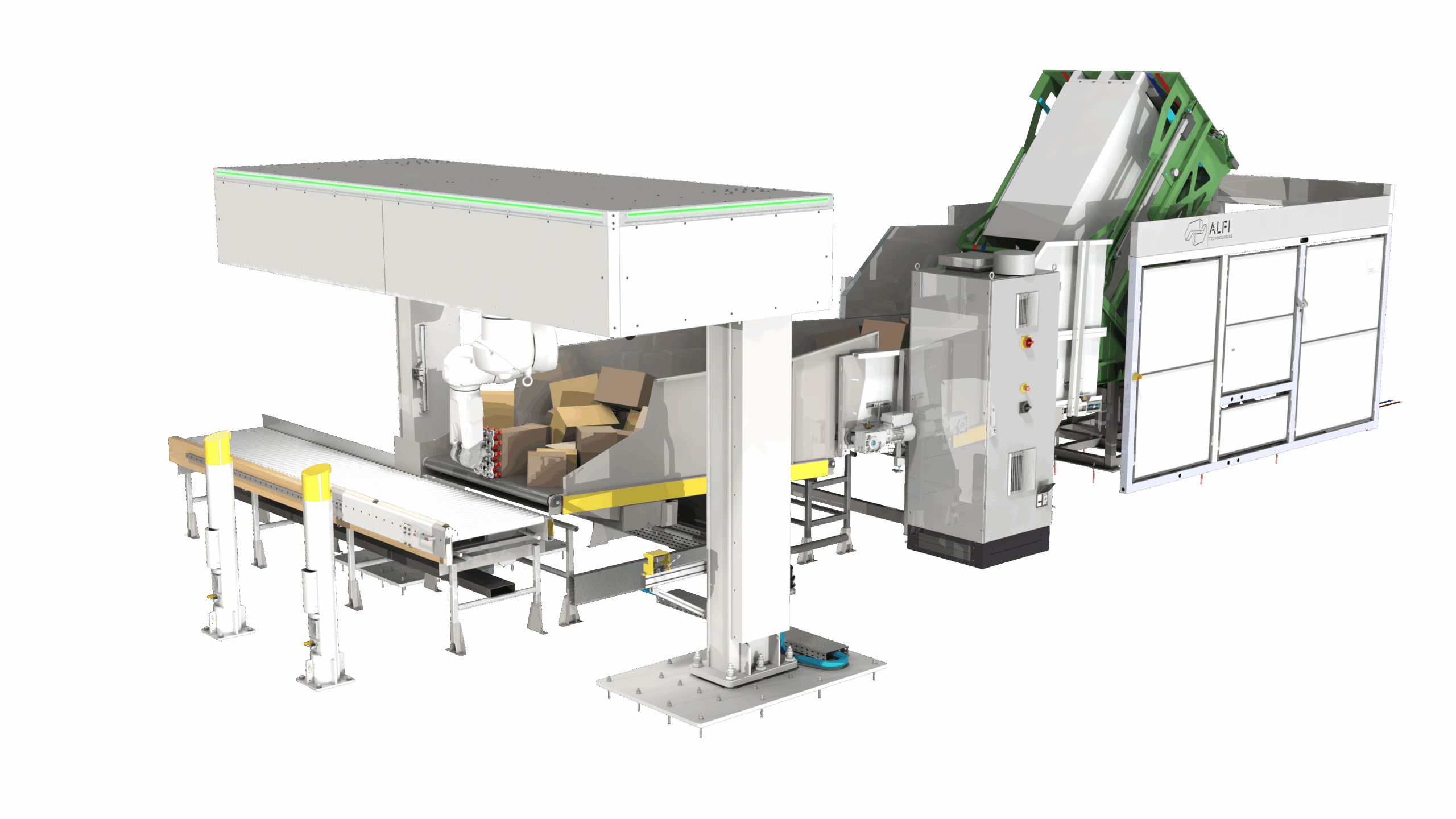

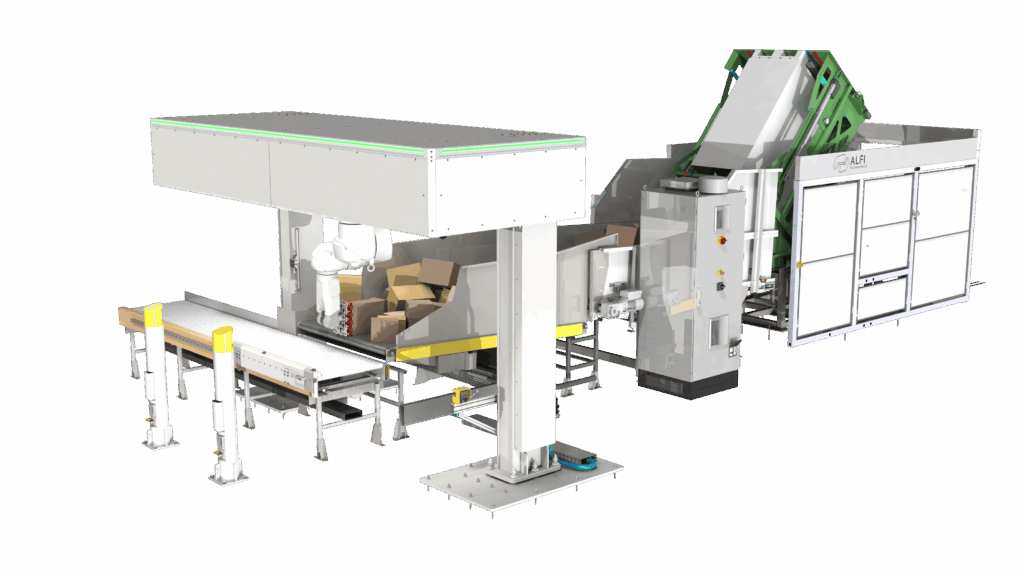

ParcelStreamer: One solution from infeed to singulation

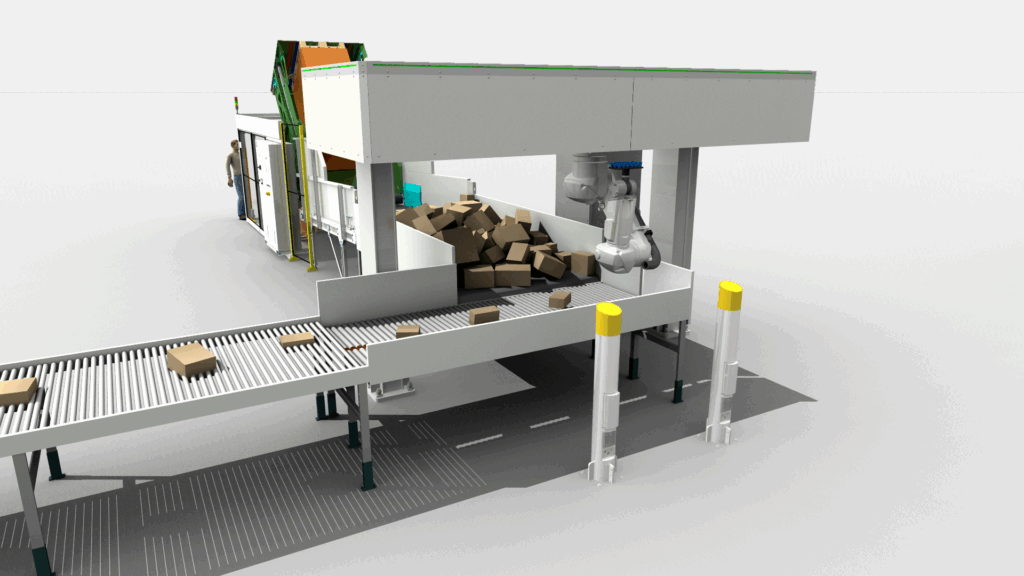

A space-efficient, highly automated solution that combines parcel infeed and AI-based robot singulation in one cost-efficient system. Designed for both tight retrofits and new parcel centers, it handles all common parcel types, weights, and sizes with a high degree of autonomy and proven real-world performance.

What is the Parcelstreamer ?

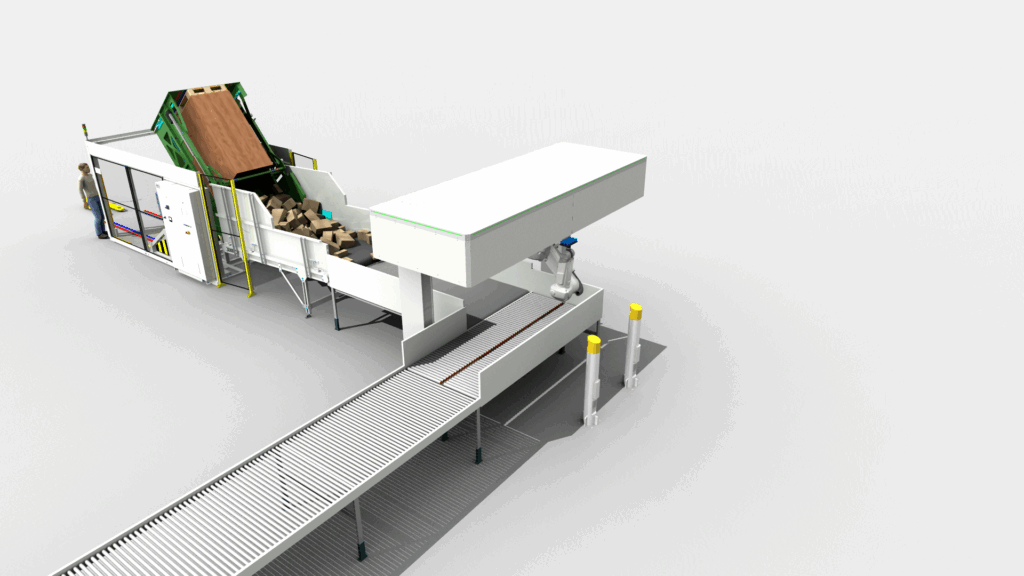

ParcelStreamer is an industry-proven system that uses electric tipping as an infeed method and AI-based robot singulation. It turns a 3D-bulk into a 1D-stream of parcels on less than 50m² with a throughput of up to 1800 parcels per hour.

In the process, the electric tipper smoothly tips the parcel container (trolley or pallet) onto a short conveyor section that feeds the bulk directly to a robot. With a patented approach to picking, parcels are then efficiently placed in a line onto a roller conveyor- ready for scanning and sorting.

Why choose the parcelstreamer?

ParcelStreamer handles parcels of any geometry up to a weight of 35 kg and a size of 120x70x70 cm. It combines latest technology for both tipping and singulating into one future-oriented and easy to implement system.

It comes with the upsides of automation such as consistency and scalability while following a low-risk design approach: features like a manual fallback mode help reduce the risk of unexpected downtime, ensuring the parcel center can keep operating in case of singulation issues. An implementation time of less than a week further reduces disruptions in your operations and enables early value creation.

Advantages of THE parcelstreamer

High parcel flow

Parcels of any geometry up to 35 kg, and a size of 120x70x70cm. Throughput of up to 1800 parcels per hour

Reduced retention rate

During the unloading process, the rotation of boxes is adaptable in acceleration and speed, which allows an ideal flow and a reduced damage rate of parcels in the entire system.

Energy efficient

Designed for energy efficiency, ParcelStreamer’s electric unloader e.g. averages only 2 kW/h in power consumption — roughly one-third of a comparable hydraulic unloader.

Increased lifetime

The unloader, one of the most heavily used components in ParcelStreamer, is equipped with a strong and reliable geared motor. Compared to hydraulic unloaders, this significantly reduces wear and highly contributes to the overall increased lifetime of the system

Low maintenance cost

Compared to a hydraulic unloader, ParcelStreamer’s tipper only requires maintenance 1 to 2 times per year and no hydraulic expert on site. The singulation robot comes with an easy to understand operating panel, not requiring an expert on site either.

Fast integration

Integrated into your system within one week after site evaluation.

Silent

The ParcelStreamer is particularly quiet, less than 70 DbA. It allows operators to work without headphones and earplugs

Quick Return On Investment

The ParcelStreamer requires minimal staffing while replacing up to three operators for manual unloading and singulation, resulting in an ROI of less than two years..

Human fallback

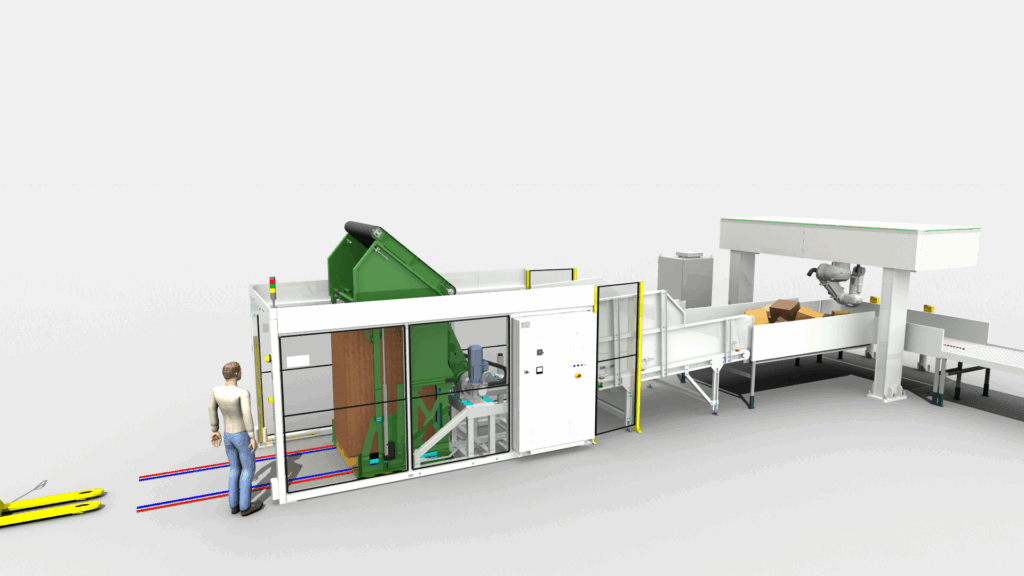

ParcelStreamer easily turns back into a human workstation at any time.

Ergonomic

Automation reduces handling-related accidents and ensures a safer working environment

Standard ParcelStreamer Cycle Description

Step 1

Step 2

Step 3

Step 4

PARCELSTREAMER Technical features

Specifications

- Throughput: up to 1800 pph

- Footprint: less than 50 m²

- Parcel weight: up to 35 kg

- Parcel size: up to 70x70x120 cm

Electrical Tipper:

With 25 years of experience in automated handling solutions for loading and unloading parcels, ALFI Technologies has developed and exceptional know-how to improve the performance and productivity of logistics centers. This expertise comes from hundreds of systems designed and built for industrial processes, combined with a long-standing collaboration with major players in parcel transport and postal logistics.

Singulation Robot:

The singulation robot used is the TITAN by German company robominds. It is the most flexible robot system for parcels singulation to date, and is able to handle all common parcel types, and weight – all on 10 m².

More information about TITAN: https://www.robominds.de/solutions/titan