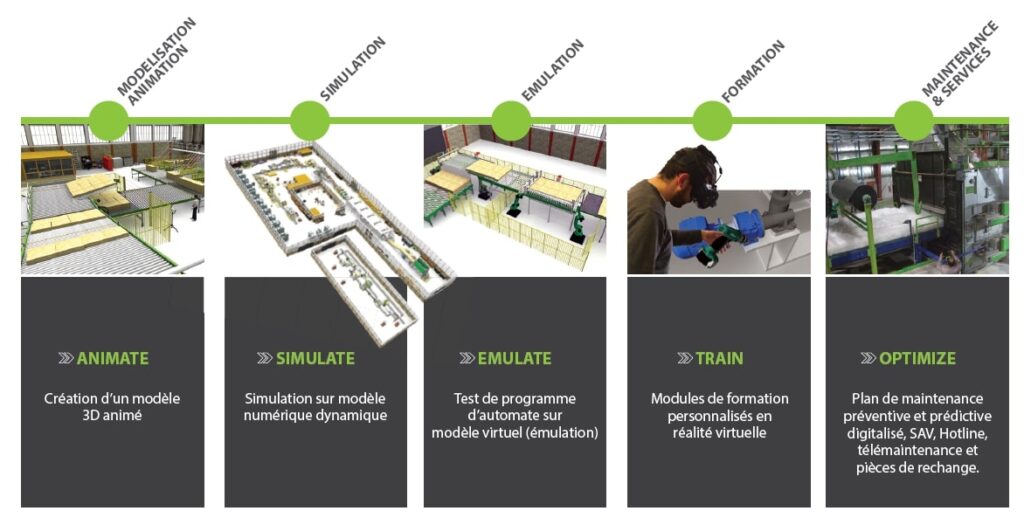

Digital twin

INDUSTRY 4.0 TO BUILD THE FACTORIES OF TOMORROW

ALFI Technologies uses the best of Industry 4.0 technologies (virtual reality tools, emulation or IoT) to create the digital twin of your production line.

This new approach allows us to support our customers in the development of their project, from the drafting of their specifications to the start-up and operation of the line.

This support service for ALFI Technologies’ customers received the label “Vitrine Industrie du Futur” (Industry of the Future Showcase) from AIF (Alliance for the Industry of the Future).

Your virtual factory by an industry expert

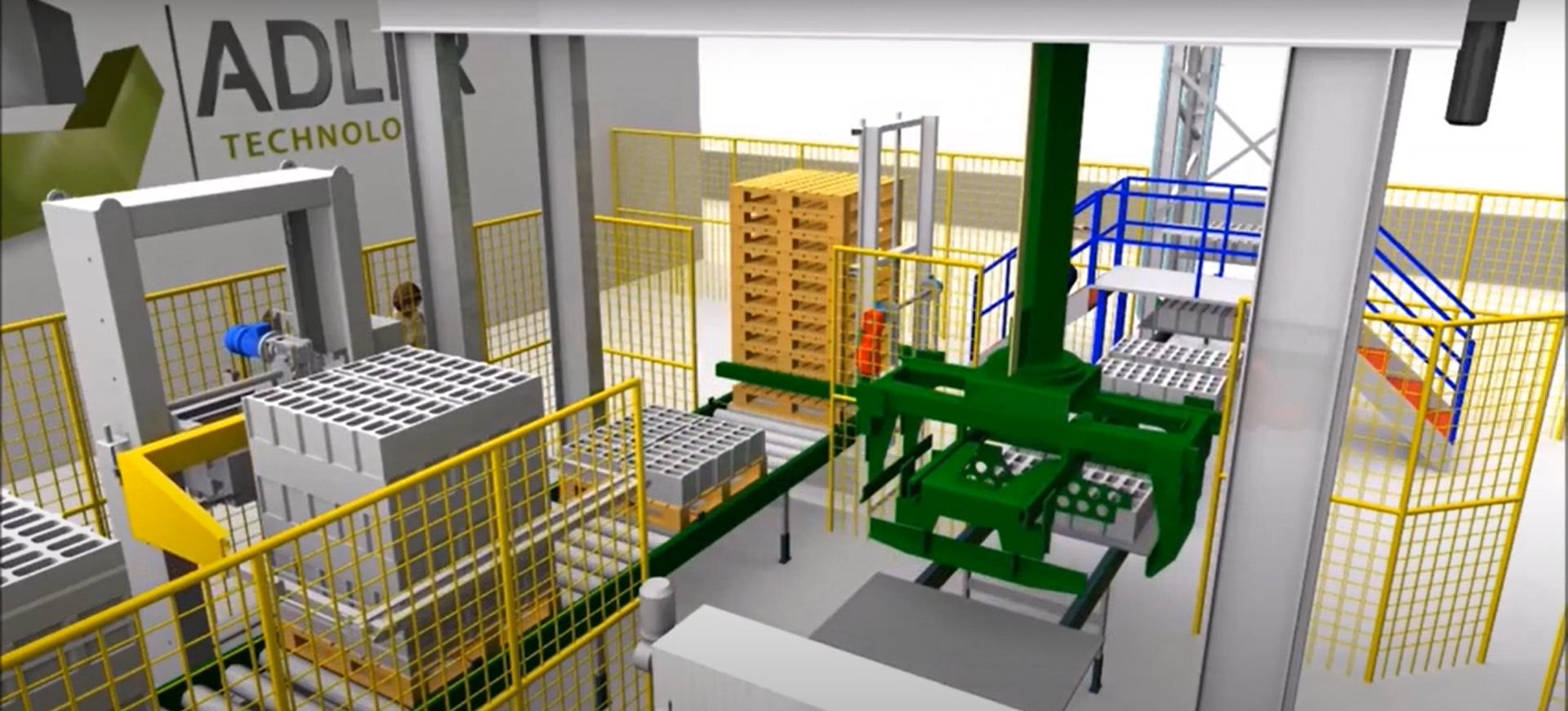

ALFI Technologies develops a digital prototype of your factory to support you from the preliminary projec to the production : animation, simulation, virtual commissioning, training, maintenance and optimization.

This digital twin combines the latest technologies of virtual reality and emulation (ALFI InSimul) and the most efficient IoT solutions (ALFI InUse).

Support from preliminary project to production

ALFI Technologies has been using digital technologies for many years to design, test, sell and train. Today, the group puts this expertise at your service by proposing an offer dedicated to the development of the digital twin of your project.

This offer is organiazed in 5 distinct phases: project modeling (animated 3D model), simulation (dynamic digital model), emulation (testing of PLC programs), trainingand maintenance.

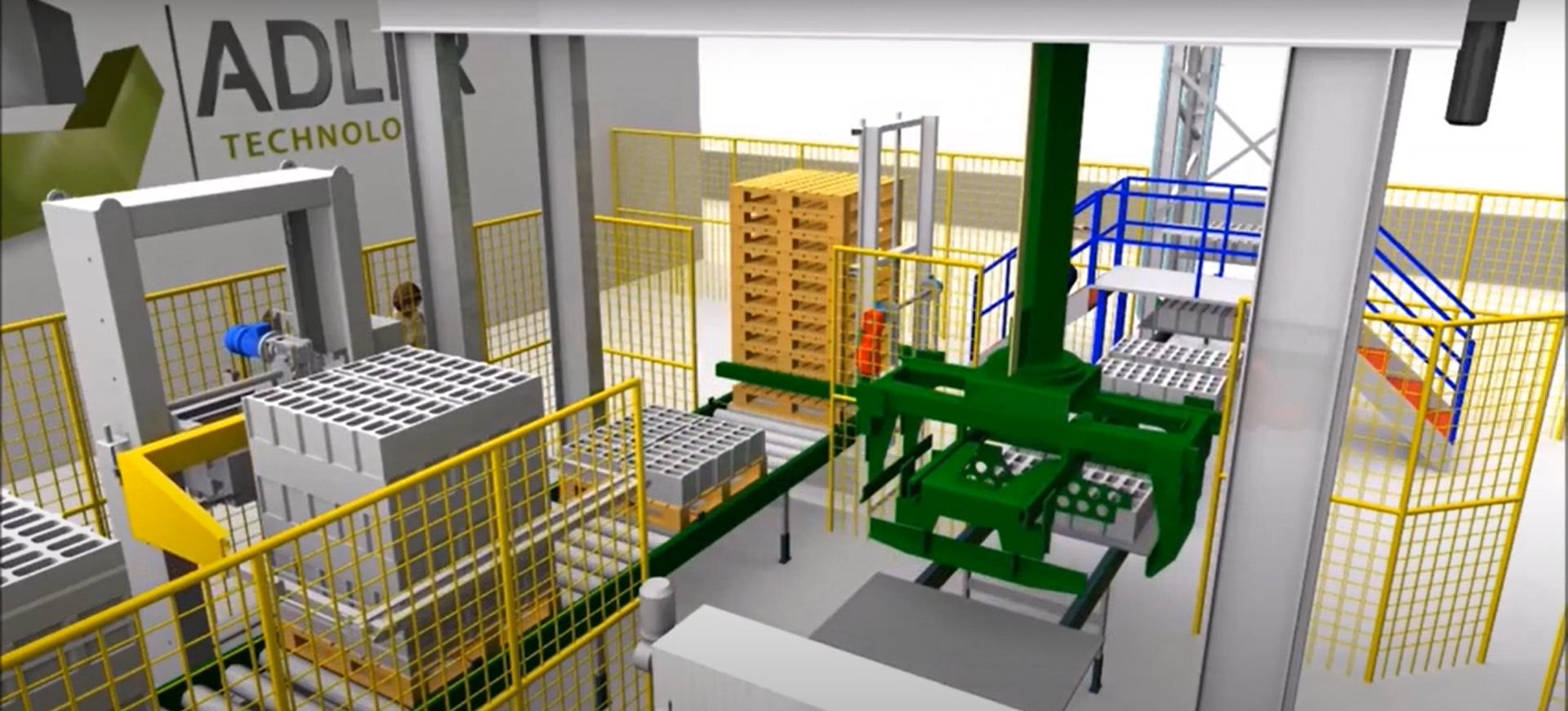

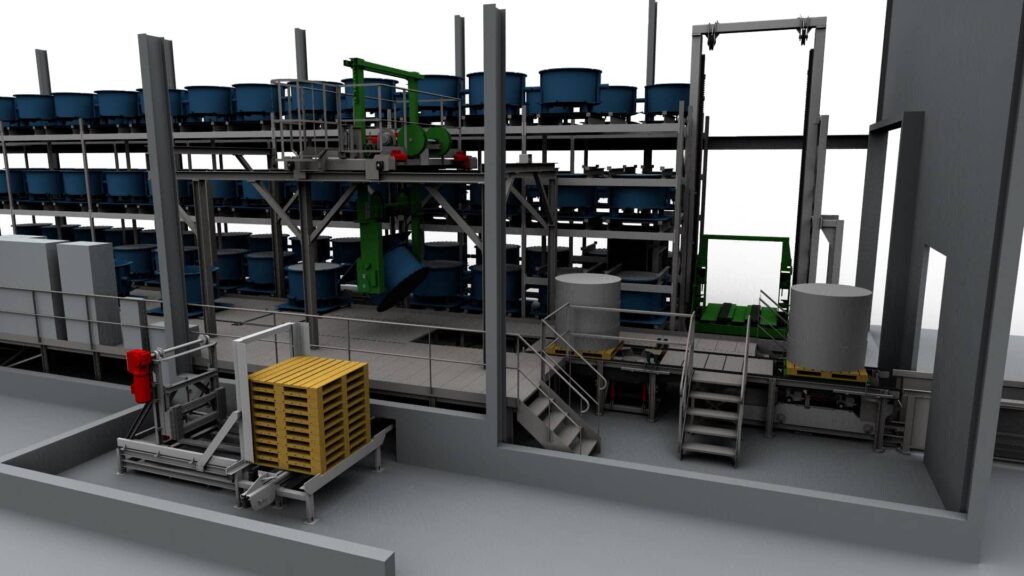

Modeling and animation

Creation of an animated 3D model

- Better impregnation and understanding of the project in 3D

- Validation of spaces and ergonomics

- Dynamic sharing of information with your teams (virtual and augmented reality, 360° realistic video, 3D PDF…)

- Valuation of your project with your customers

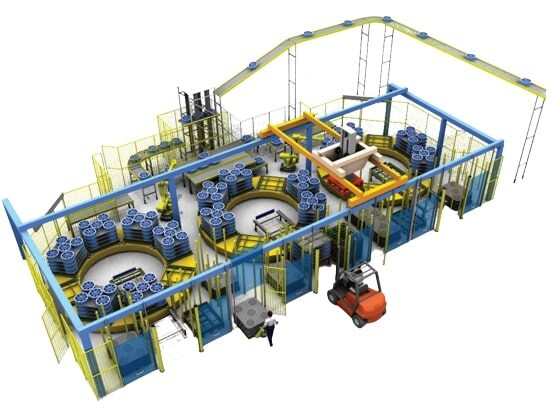

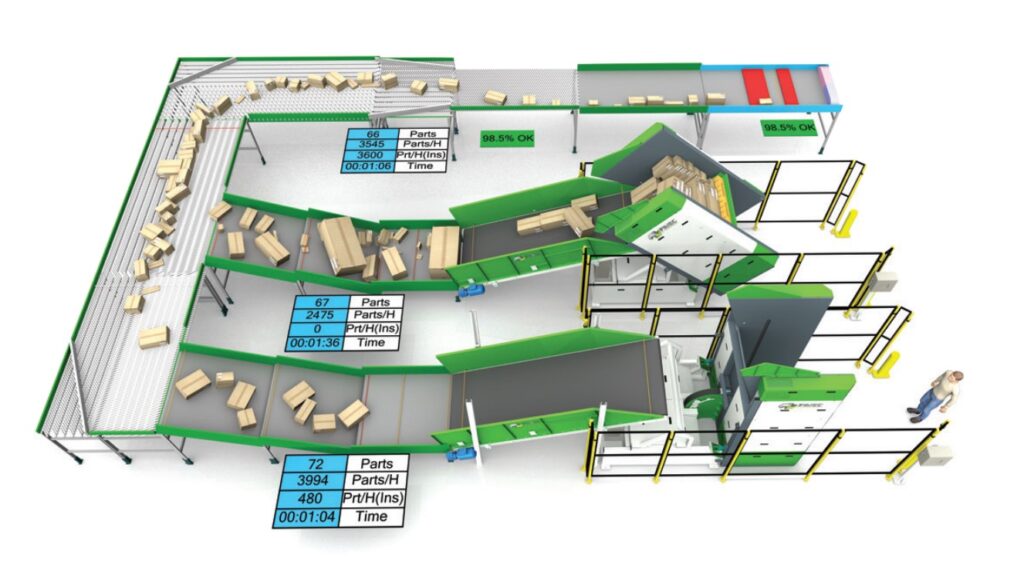

Simulation

Simulation on a digital dynamic model

- Response to a problem by simulation (by discrete or continuous elements) according to different scenarios

- Validation of production rates (simulation report)

- Testing of products’ physical reactions

- Integration of hazards (stochastic processes)

- Securing the project before investment

- Support to get used to the production tool

Emulation

Testing of PLC programs on virtual models (virtual commissioning)

- Debugging, reliability

- Anticipation of the tests before the physical start-up

- Optimization of real test times

Training

Customized training modules in virtual reality

- Training model that replicates your environment

- Total immersion in virtual and collaborative reality

- Practical, attractive and playful training

- Training without risk (breakage, injury…)

- Cost reduction (optimization of training time, no rental of specific equipment…)

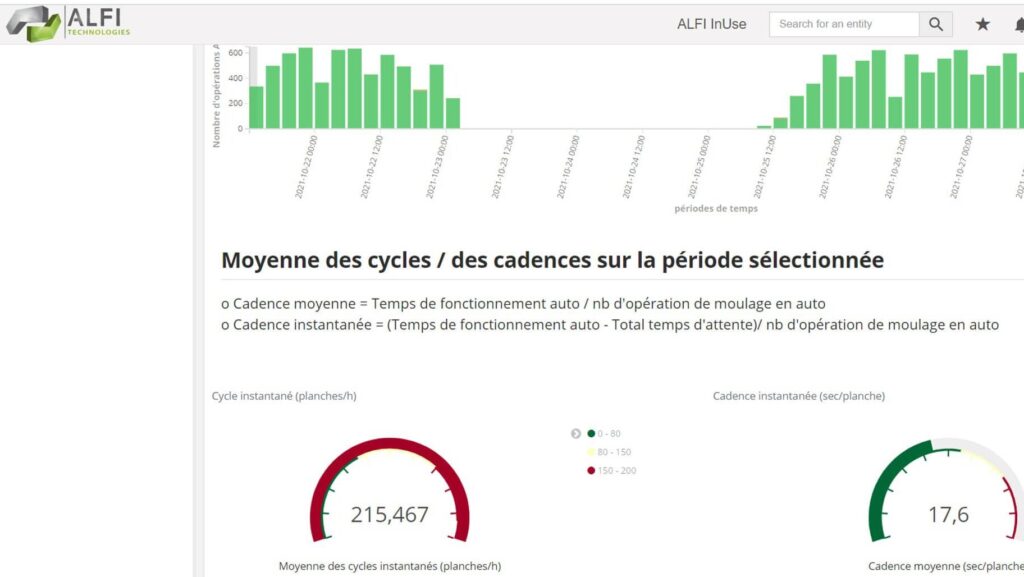

Maintenance and services

Plan de maintenance préventive et prédictive digitalisé, SAV, Hotline, télémaintenance, et pièces de rechange grâce à notre Plateforme web IoT ALFI InUse.

- Digitalized preventive and predictive maintenance plan

- Automated and documented production reports

- Online diagnosis

- Optimization of operations, measurement of cycle times and waiting times

- Operator assistance (tutorials, technical documentation…)