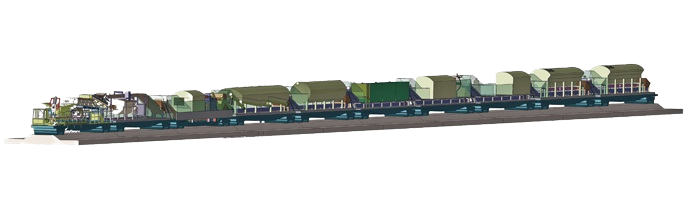

ADLER concreting train

Train for tracks concreting

ALFI Technologies, expert in engineering, turnkey solutions and equipment dedicated to the concrete building material industry has developed the automated concreting train, a unique process and innovative technology.

Based on the company’s exceptional mastering of concrete, both the material and its processing, it remains an unmatched solution for continuous concrete production dedicated to difficult work areas and hard environmental conditions.

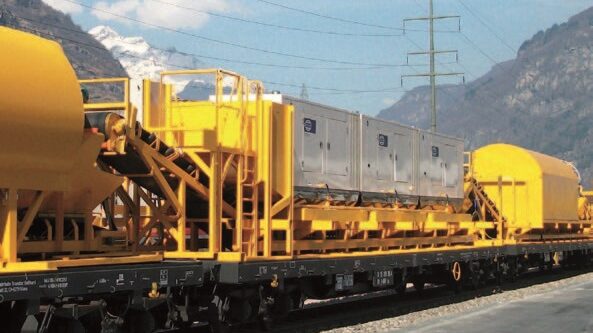

In 2010, a train built by ALFI Technologies (ADLER) was used to build the Saint Gothard tunnel. Click here to learn more about this exceptional project.

Continuous concrete production process

This fully automated solution includes a concrete train (the key to the solution) – true mobile concrete plant that guarantees a continuous process for long-term production at industrial scale, a concrete shuttle that makes the link between the train and the dispenser unit, a concrete dispenser unit and a storage plant. ALFI Technologies makes it adaptable, clean, safe and efficient while meeting the most complex quality specifications.

- Adaptable and flexible trains

- Concrete quality guaranteed

- A safe solution for operators

- A clean concreting process

Equipment of our concreting train

Pump wagon

Equipped with a concrete mixer conveyor, and a pump, it includes a concrete arm or a telescopic conveyor to supply concrete to the shuttle or directly onto the tracks.

Waste wagon

The waste wagon collects all mixes of inadequate quality and cleaning water waste. Satisfactory mixes are transferred to the next wagon.

Mixing wagon and control room

Mixing plant unit that handles: weighing conveyors for aggregates and cement, hopper for aggregates and 60 m³/h shaft mixer. Automatic weighing stations for cement, water and aggregates. Mixing cycle through PLC Management system equipped with a screen, a keyboard and interfaces. Sound proof and comfortable air conditioned control cabin.

Cement wagon

Cement wagon 50 T watertight welded wagon. 3 cement screws to transfer cement from one wagon to the other and to the cement weigher.

Water wagon

Water wagon 50 m³ steel proof tank. A main conveyor for aggregates is installed on the wagon platform with lateral protections on all accessible surfaces.

Power wagon

690 / 400 volts transformer with a main coupling cabinet to provide power to all train machinery. Sound proof diesel generator connected to the main coupling cabinet.

Workshop wagon

Wagon dedicated to maintenance work.

Aggregates wagon

Aggregates wagon 24 m³ steel hoppers. The wagon is equipped with powered conveyor belts to drain extracted aggregates from hoppers to the main conveyor belt.