Boards and laminated

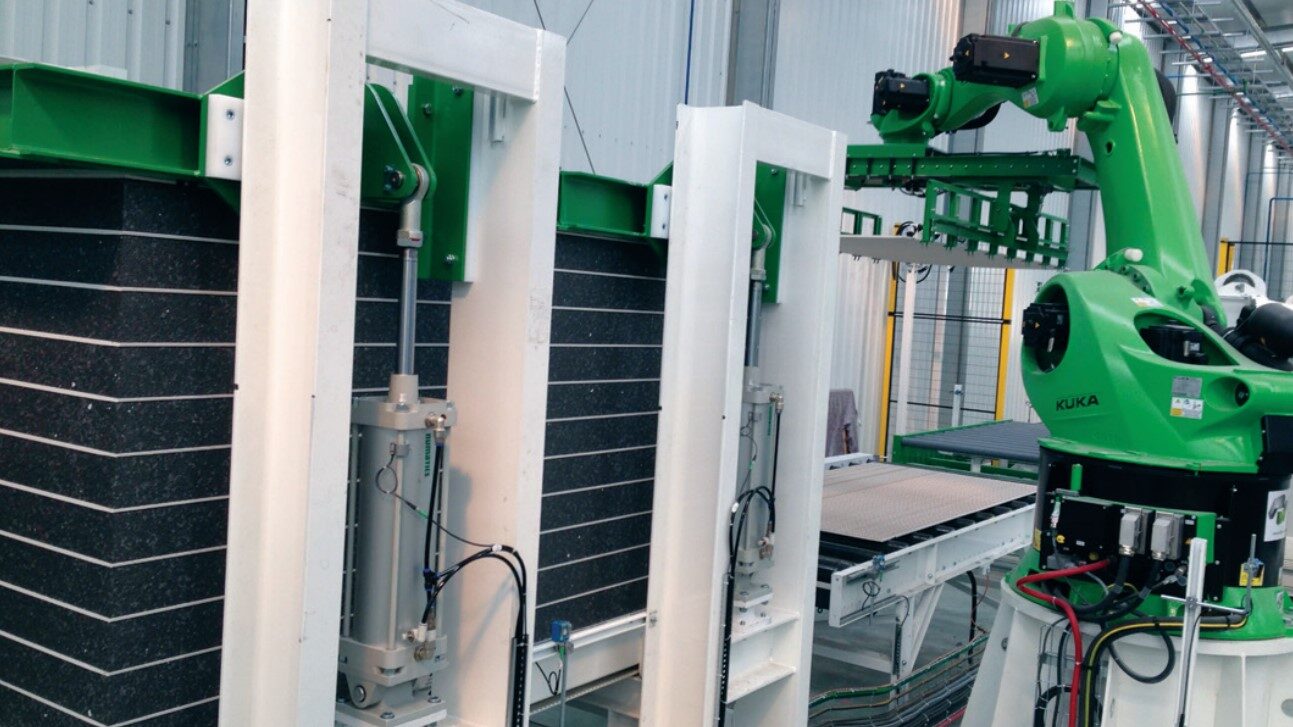

ALFI Technologies offers panel assembly lines that incorporate demolding, machining, cutting and quality control units…These lines fit to the cold end production line of panels that are molded simultaneously with insulation. The group developed an extensive experience in gluing process for panel assembly

Production of insulating panels

The company got the best from robotics, mecatronics, vision… to meet capacity level and flexibility requirements of customers.

Machining, cutting or painting processes can be added to our standard lines.

Packaging modules are also available :

Different possible configurations

| Configuration | Cadence (panels/min) | Capacity (m²/h) |

|---|---|---|

| Multi functions robot | 2 panels / min | 170 m²/h |

| Gantry process | 4-6 panels / min | 350 – 525 m²/h |

| 3 robots high capacity process | 4-6 panels / min | 430 – 1000 m²/h |