Palletizing

Smart and flexible palletizing solutions

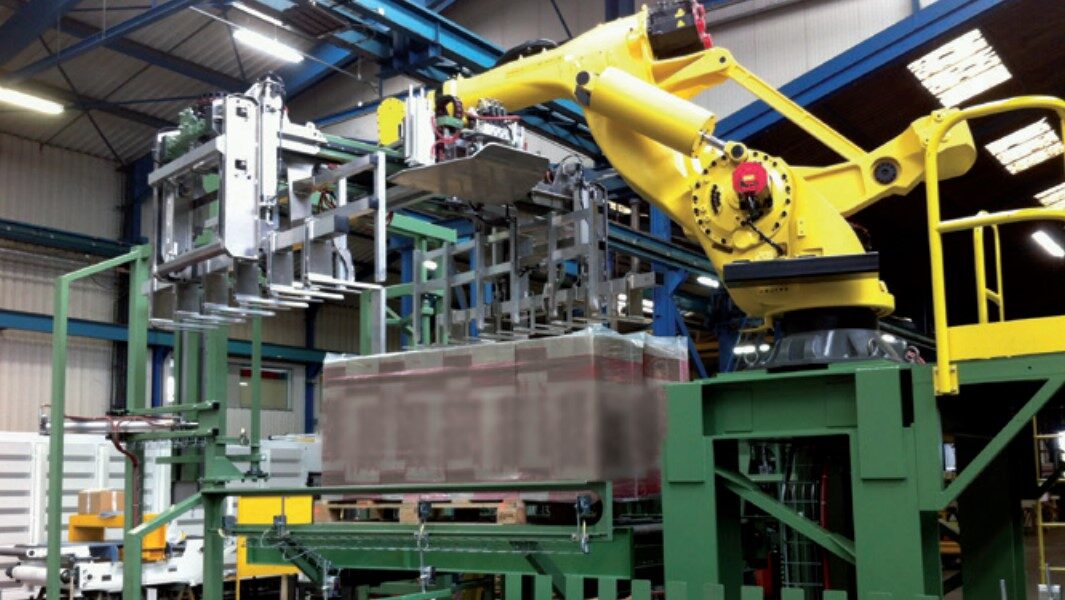

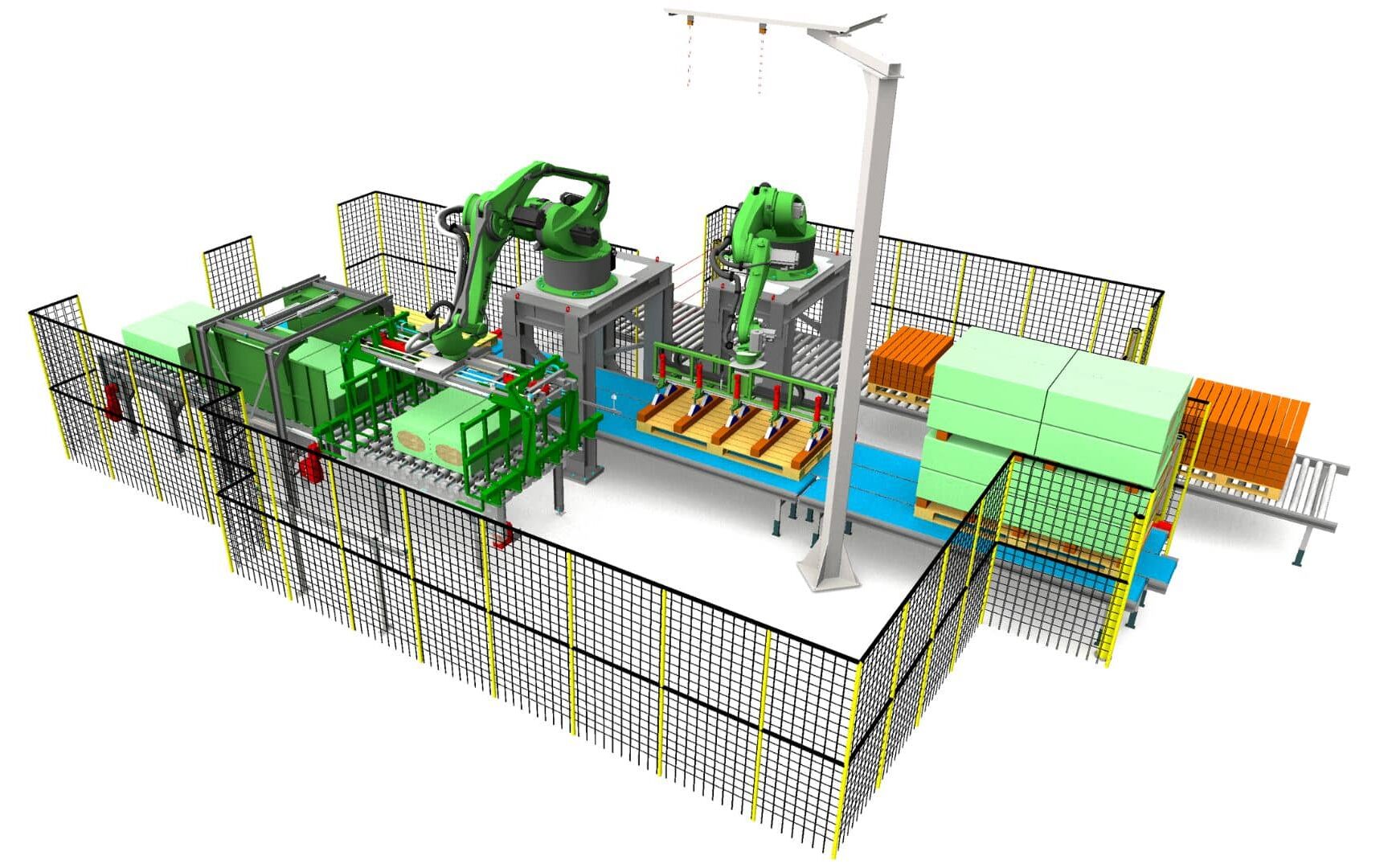

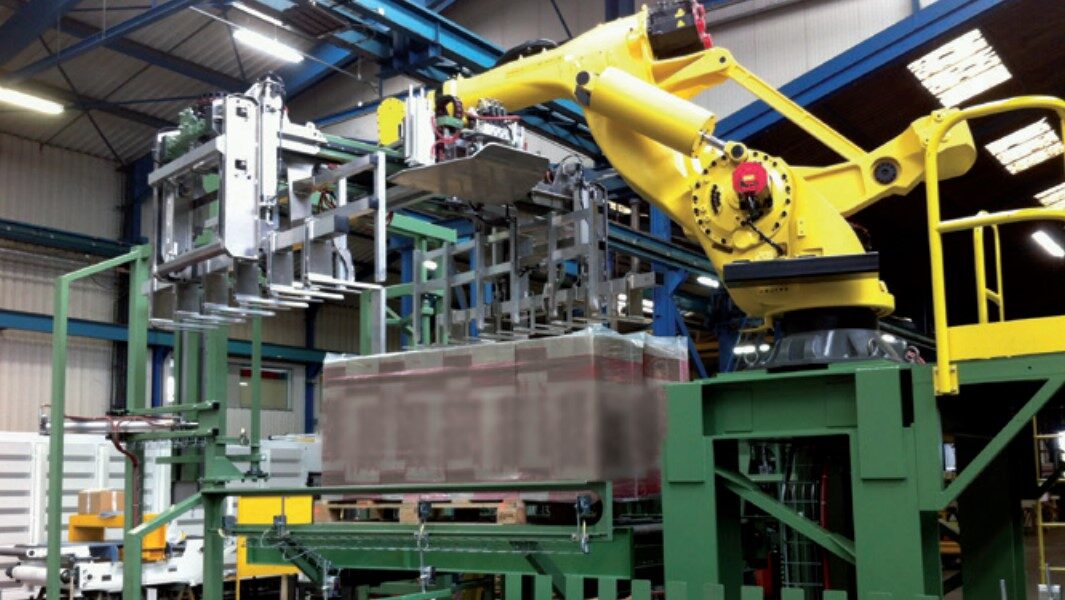

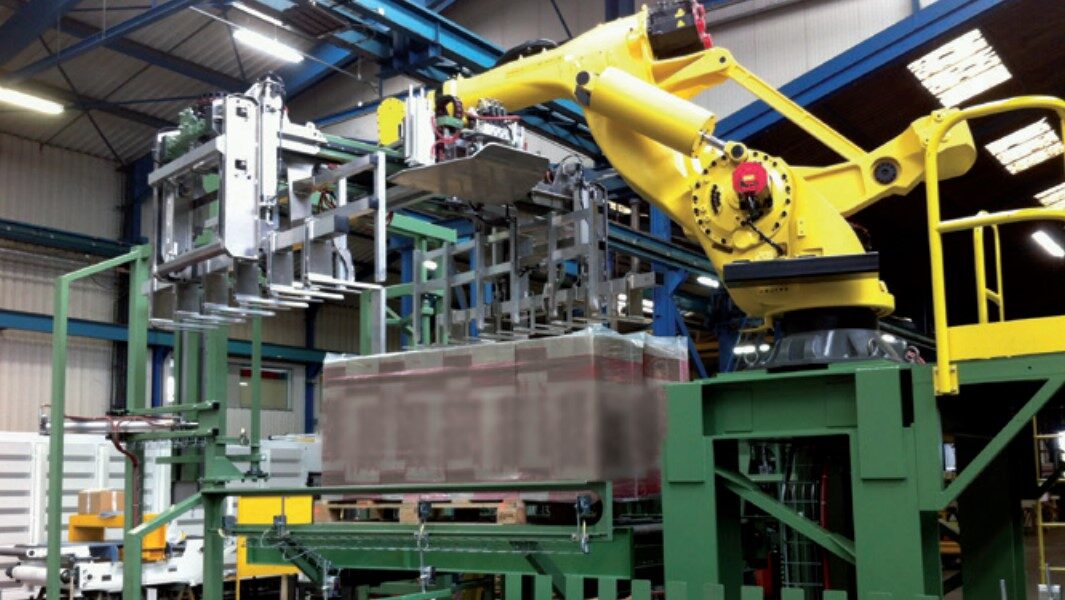

The ALFI Technologies turnkey palletizing units are flexible and versatile all-in-one solutions: wool stacked bundles centering, rotating, gluing and final palletizing operations are run in one line.

The company develops a unique expertise in the design of multifunctional and «clever» grippers: palletizing of numerous formats is possible without changing gripper.

Palletizing unit adaptable to all packaging

Thanks to its innovative design, this robotized unit reconciles the creativity of marketing teams and production constraints: it automatically adapts to any new palletizing configuration, without any human intervention, and guarantees an optimal stacking quality.

This solution is already operational on several insulation production sites and completes a set of palletizing equipment that makes ALFI Technologies a recognized player in the market of high speed end of lines for the insulation industry.

Time saving

No tool changer, continuous production flow

Space saving

A single robotized unit for all the production

Budget

One output line for all your production

Quality

Optimal quality thanks to the palletizing technology with stripper

Capacity

Up to 5.5 cycles / mn or 44 packs/m, (600x600x1200 mm).

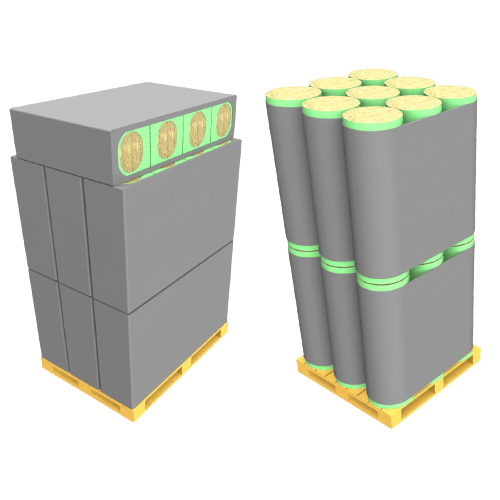

The different palletizing possibilities

Palletizing on wedges

Packs and crossed packs

Multipacks, horizontal & vertical

Long length pallets or multipallets

Palletizing units adapted to your needs

| Width of the pallet | Length of the pallet | Height of the pallet | Capacity | |

|---|---|---|---|---|

| Flexible palletizing unit | 0.8 m to 1.3 m | 1 m to 3 m | 1,2 m to 3 m | Up to 5,5 cycles /min |

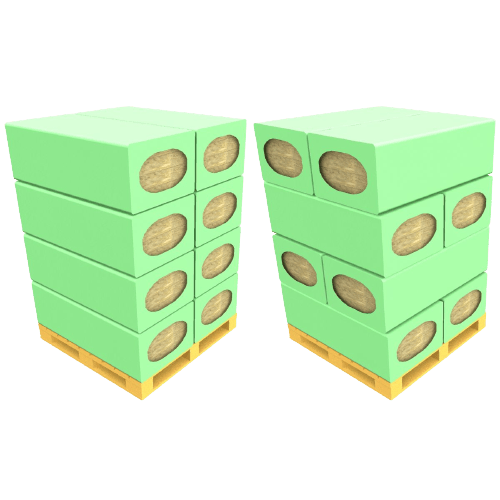

No pallet palletizing

Palletizing lines designed by ALFI Technologies are also suitable for palletizing “without pallet” or paquettizing. The company has developed solutions to replaces palletizing on wood pallets by setting wedges/kickers.

This equipment enables customers to palletize insulation materials using wedges made of the same material as the one which has to be packaged. These wedges can be reused as insulation material on the construction site and participate in reducing waste on building sites.